Magnetic Print Bed

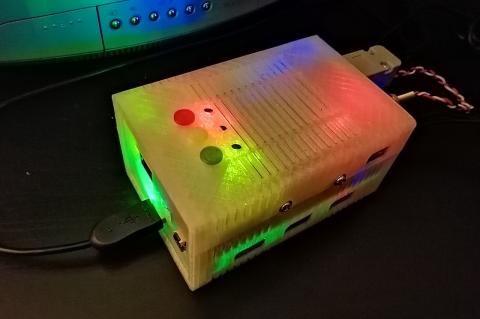

MiSTer - 3D printed case

Laser module on 3D printer

E3D Cyclops clone extruder build

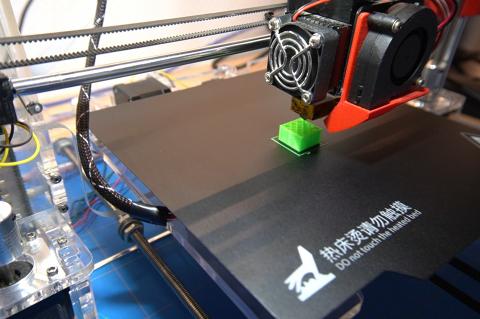

Printing with ABS

The most important advantages of ABS are impact resistance and toughness. Lego is made from ABS. It will also not deform in hot water, compared to PLA. On the downside ABS is hard to print. You need very hot printbed (around 110 degrees Celsius) and Kapton tape, so the first layer will stick properly. ABS can also warp and curl. There are also other issues in the Marlin firmware that need some attention.

PSU grip

Building Volcano Bowden extruder

If you are impatient and don't want to wait too long for your print to finish you can look for a solution in the E3D Volcano hotend. It is able to extrude filament a much greater speeds than a normal (V6) extruder. But it comes at a price of sacrificing the print quality.

Leaking hotend extruder repair

It can happen that molten filament can leak from the hotend. This usually happens when there is a gap between the heat break hotend throat and the nozzle. This is the result of poor assembly of the extruder's hotend part.